| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

Posted By: Doubting_ThomasPosted By: lineweightThe conductivity of steel is such that we can pretty much ignore the length of any heat path through the steel, or the cross-sectional area perpendicular to the heat paths.

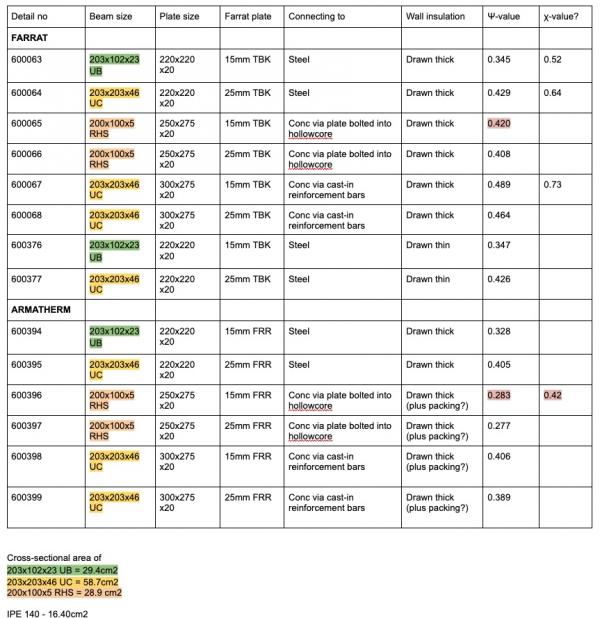

I don't quite get what you are driving at in this statement but what you are describing generally is the difference between what are called linear (psi value, W/m.K) and point (chi value, W/K) thermal bridges.

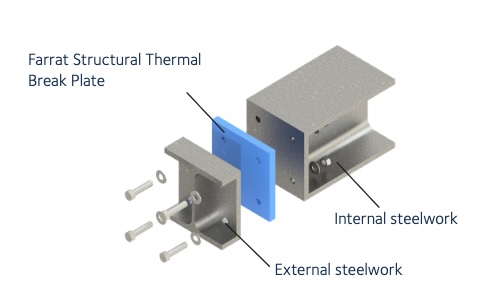

There is a distinction in units, but also in the way that they are remedied. A linear thermal bridge can usually be resolved through adding other layers in the wall build-up, whereas a point thermal bridge will usually, by necessity penetrate through all these layers (unless thermally broken with a structural pad as described in the posts above) and is thus often harder to design out.

Others can probably comment on their thermal equivalence or otherwise (I'm not convinced), but I'm struggling to see why you'd want to describe them in the same way when they aren't likely to be used for the same thing in reality.

Posted By: GreenPaddyLineweight, does the simple calculation I suggested above not give enough information ..."to decide what's the sensible thing to do"? Pursuing a super accurate answer to 3 decimal places with a fancy model doesn't feel like a sensible use of time.

The quantity of steel outwith the thermal envelope only matters in that the more steel, the closer the steel will stay to the adjacent outside air temp. ie. lots of steel, and it will not be influenced by the heat coming from inside. But the heat flow would, in simple terms, be fixed with an assumed (guessed) temp differential, creating the energy driving force.

Posted By: lineweightdoubling the thickness of a plate of steel would not have a significant effect on the rate of heat lossThat's true but it does matter in some situations. In the case of a steel column standing on cold ground for example, the rate of heat loss depends on the cross-sectional area that is in contact with the cold ground, so doubling the thickness of an I-beam would double the surface area and thus the heat loss (except that beams stood on end often have a flat plate welded to the end to connect them to the ground that vastly expands the surface area anyway!)

Posted By: WillInAberdeenSeems to me that the most significant heat transfer resistance (insulation if you like) is the surface film resistance Rsi/Rso of the steel where in contact with the air. The two examples have different amounts of area exposed to air on the top/bottom surface.