| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

Posted By: cc64at the cill carrying the lion's share of window weightThere's no reason for the sill to carry the window's weight - if it is screwed to the supports through its sides, then those vertical supports carry most of the weight.

How would you suggest protecting this arrangement from the elements, particularly at the top of windows not directly under the eavesDepends on whether aesthetics are important or not. If not then we protected an exposed construction similar to this over winter with a piece of DPM taped to the top (using Sicrall tape). It lasted fine for the six months or so it was exposed, and could have been redone at any time to extend the length of exposure if necessary.

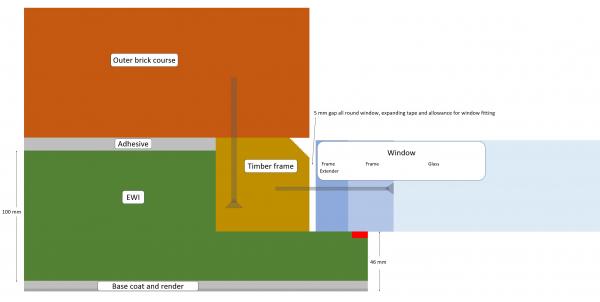

Posted By: tonyI would make the new windows wider than the opening then fix through the frame or frame extension into the old outer skin.

Ideally a bit of the real new window frame would have the reveal plaster onto it