| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

Posted By: Doubting_ThomasPosted By: lineweightIs it offered as a 'system' by GBS? In other words if you give them the dimensions, weight of your door frame etc can they confirm whether this detail will work?

I don't think so, I'm afraid.

From memory I ended up doing some rough calculations that others on here helped out with. See second half of this thread: http://www.greenbuildingforum.co.uk/newforum/comments.php?DiscussionID=11503&page=1

The safety factor was big enough that I felt comfortable using it. Plus I also checked it with the supplier of the Isoquick and the Sliding Doors and it's a fairly standard approach.

Posted By: lineweightComing back to this... further investigations brought me to "structural cavity closers" and products from Cavalok who seem to be part of Eurocell.

This has been mentioned in a previous thread, I see:

http://www.greenbuildingforum.co.uk/newforum/comments.php?DiscussionID=9392

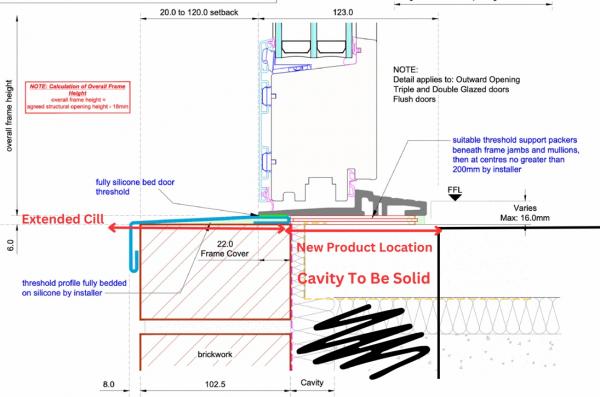

It's hard to find any very useful information on the Eurocell site. I had a bit of a confusing conversation with one of their technical people, where I tried to explain that I wanted to understand whether they can offer something that will span a cavity under the sill and take the weight of a door/window installed above it. His answer seemed to be that this would never be an issue because the frame itself can simply span the cavity, but that's not what the window installers I've talked to have said. They always want a continuous solid base across the depth of the frame.

Anyway - they pointed me to here:

https://www.subframes.co.uk/cavity-closers/structural-door-packs/

And I'm making some enquiries with them. But I think that this system is not actually designed to be load bearing across the bottom horizontal member - it's more that you can fix directly into the jamb closers and they will transfer the load into the outer and inner leaves.

Posted By: djhWell, you could fasten the compacfoam to whatever forms the edge of your timber floor structure. I presume there's some kind of perimeter beam. Might need to check the engineering - double up the beam or something in that area.

Posted By: lineweightthe compacfoam could then sit directly onto the masonry wall, like the timbers