| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

b5b8.jpg?AttachmentID=8393)

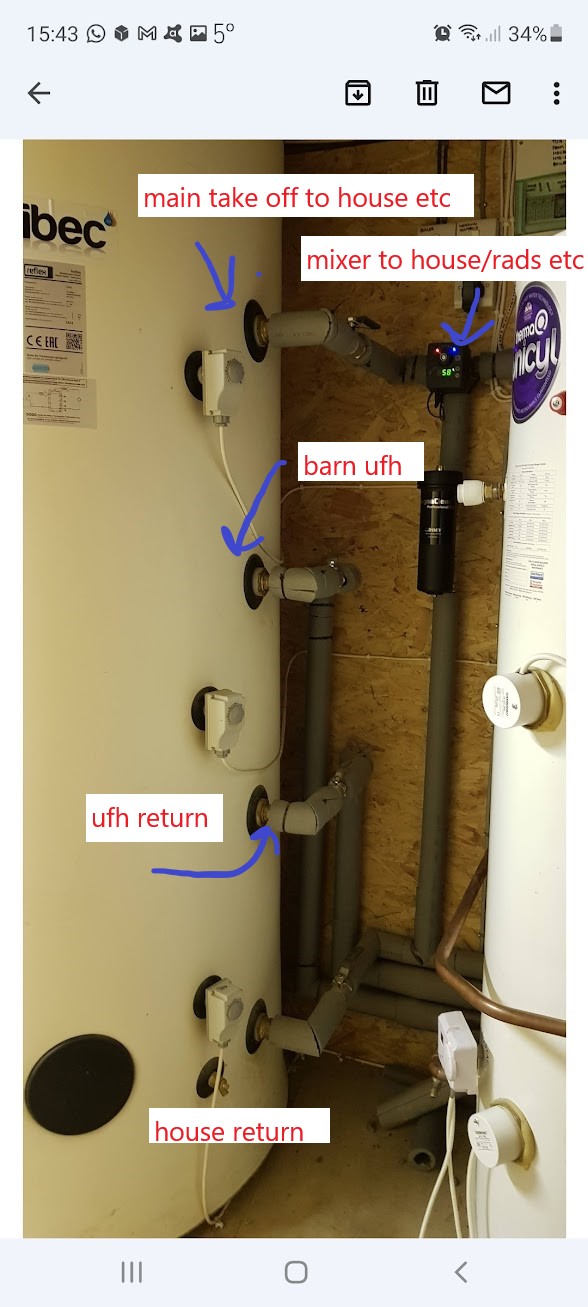

Posted By: Noodlethis is the system by the way. perhaps its a 1000l buffer, but the stats have never worked properly so I just have 1 that keeps the middle around 65 degrees...i mean, that could also be part of the problem!!

The problem with the system I have is that the Barn UFH is taken off mid height but the buffer water there cools down quickly vs the top and so if I put the pump stat at the top 1/3 the barn UFH supply quickly cools to mids 50sC while the top take off is still at 65+ >

Posted By: Noodlethe Barn UFH is taken off mid height but the buffer water there cools down quickly vs the top and so if I put the pump stat at the top 1/3 the barn UFH supply quickly cools to mids 50sC while the top take off is still at 65+ .

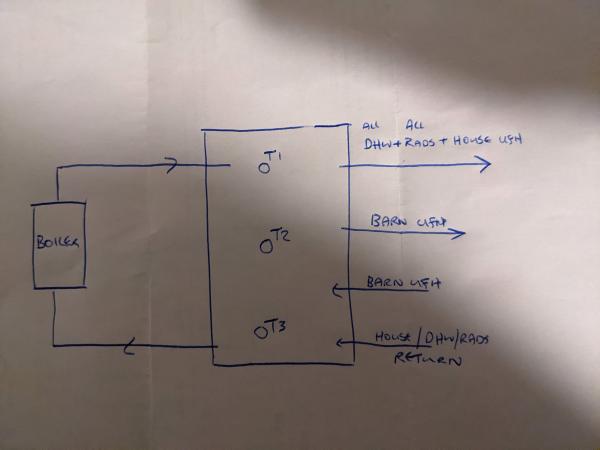

Posted By: Peter_in_HungaryYou show the barn UFH coming of the center of the TS but also show it tee'd off from the top output. The house also has UFH and both have rads.

Posted By: Peter_in_Hungarys Jeff said 8000 l oil or 15 ton pellets is a lot of fuel. Do you know where the heat is going?

Posted By: Peter_in_HungaryI am assuming the boiler / TS is in a boiler room

Posted By: Peter_in_HungaryOil boilers don't typically modulate, is this the case with the boiler you have installed? If so it may be worth using the TS to prevent short cycling.

Posted By: Jeff Bhe price for pellets that you quote is extraordinary

Posted By: Jeff BI fully understand your pain with the pellet boiler after having struggled with mine for over 7 years. The price for pellets that you quote is extraordinary - how can that increase be justified!!?

Posted By: Peter_in_Hungaryheat meters on each house

Posted By: NoodlePosted By: Jeff BI fully understand your pain with the pellet boiler after having struggled with mine for over 7 years. The price for pellets that you quote is extraordinary - how can that increase be justified!!?

rising oil prices for transport, and then most the supply chains for timber and waste were from russia/ ukraine...

it will likely look alot different in a yrs time but still!

Posted By: ArtiglioHowever it rather looks to me as though somewhere in the supply chain it’s been decided to track the gas price on a kwh basis

Posted By: NoodlePosted By: Peter_in_Hungaryheat meters on each house

do you have a link to such meters?

Posted By: NoodleWould you generally suggest then that the Barn UFH is teed off the top and then I don't have to heat the middle of the buffer tank so much and can leave it to stratify properly? During spring/summer I move the buffer stat to the top of the buffer tank as dont use UFH and barley used any pellets then.

Posted By: NoodleGenerally the buffer tank and boiler seems to struggle to bring it back up to temp while calling for heat load and seem to only do so once majority of heating circuits closed. This is an issue with both the pellet boiler and with the oil boiler which is currently being used. Ive attached a clearer diagram.

Posted By: NoodleI have noticed that as cold water floods the bottom of the tank the middle cools down to 45/50ish while the tops stays in the 60s.

Posted By: NoodleI have wondered if the boiler flow is in effect being pushed into the store and the majority heading straight across to the DHW/Rads takeoff and so almost feeding directly to the heating circuits instead of heating the store up, as it doesn't have an internal coil/ baffle plate? Is this possible/ likley and if so, short of replacing the store with one with a coil would bringing the boiler feed in a little lower down help/ stop this?

Posted By: NoodleFinally to try and limit my heating load I have been setting the store to around 65 mid to avoid heating too much water too hot and the associated extra heat loss. Would I be better off heating the top or middle up to far hotter temperature in the hope that the boiler feed/returns are hotter and the store would have a larger heat buffer and not cool down as quickly when cold heating circuits flood the store? What temp do people normally heat buffer tanks upto?

Posted By: NoodleI do have a stat I don't currently use that temporarily stops the heating circuits if the store drops below a certain temp, maybe I should use that to allow the store to get back to a certain temp after it cools down before it starts pumping heat again?

Posted By: ArtiglioThe annexe when it has guests gobbles huge amounts of energy, people see it as free and keep it nigh in sub tropical.

Posted By: NoodleI guess my main question then is should I super heat the top of the store to 70ish in the aim to give larger buffer or not. The idea isn't to get the entire store upto 60/70 top to bottom when not being drawn on?

Is the boiler/ energy use more or less if you have a higher kw boiler burning harder but shorter. Or a lower kw boiler burning longer but using less oil?

Or does it makes not a lot of difference and it's swings and roundabouts.

Posted By: Peter_in_Hungarycheaper to better insulate the boiler, TS and the pipes.

Posted By: Peter_in_HungaryDid your system always use as much fuel as you are using today? And have you done a detailed heat load calculation for each building? Could it be that you are using as much fuel as you are because that is the heat load of the buildings,

Posted By: GreenPaddyDo you find the house/barn cooling down even when calling for heating on the UFH/rads?

Posted By: GreenPaddyI've attached a quick sketch of the above

1 to 22 of 22