| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

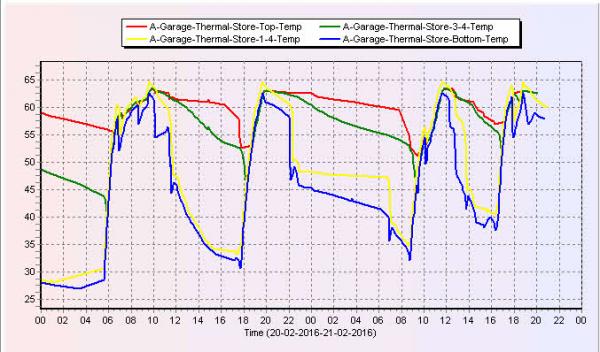

Posted By: SteamyTeaYou also need to sense the air temperature around the tank.

Ideally you need a heat meter on the inlet and outlets or you end up just measure the temperature losses if you are not careful.

1 to 5 of 5