| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

Posted By: willie.macleodExtruded polystrene will have a higher compressive strength than expanded (i.e. look for XPS instead of EPS)

Posted By: Saint500kPa and 700kPa compressive strengths so that's around 0.5N/mm2 and 0.7N/mm2The “around” here made my smile. Like 500 g is around 0.5 kg. But only very approximately, you understand?

Posted By: Ed DaviesPosted By: Saint500kPa and 700kPa compressive strengths so that's around 0.5N/mm2 and 0.7N/mm2The “around” here made my smile. Like 500 g is around 0.5 kg. But only very approximately, you understand?

Posted By: owlmanI use it as in floor insulation under concrete, but do you think if you shaped it, tanked it, with something like a tanking slurry to create a key, you could then skim/render it to create a shaped plaster form that would take weight, with a timber tread on it,- steps for instance? Just an idea

Posted By: woodgnomeAre you able to fix the XPS the same way as the Compacfoam? I need to drill and bolt the compacfoam to the edge of my slab as support for doors and sliders.I don't know of any other insulation which will take a fixing of this type. If you use XPS then you'll need to put it in a pultruded fibreglass channel or box.

Posted By: owlmanGetting the plaster/render to stick would be the problem, some sort of scrim base may be a solution.

Posted By: davidfreeboroughPosted By: woodgnomeAre you able to fix the XPS the same way as the Compacfoam? I need to drill and bolt the compacfoam to the edge of my slab as support for doors and sliders.I don't know of any other insulation which will take a fixing of this type. If you use XPS then you'll need to put it in a pultruded fibreglass channel or box.

Posted By: Cav8andrewPurenit by Puren should match the properties of Compacfoam.

Posted By: Doubting_ThomasPurenit give their compressive strength in MPa, whereas Compacoam talk about Compression stress in N/mm²

The Internorm installers have told me that they can remove the standard purenit section that the threshold comes with and fix directly into a compacfoam ground instead.

Posted By: djhI understand why you might want Compacfoam/Purenit underneath a door threshold (what is the threshold itself made from?) but why do you want it underneath the windows? Why not mount the windows directly in the main insulation?

Posted By: djhwhat's the actual load and strain under the threshold?

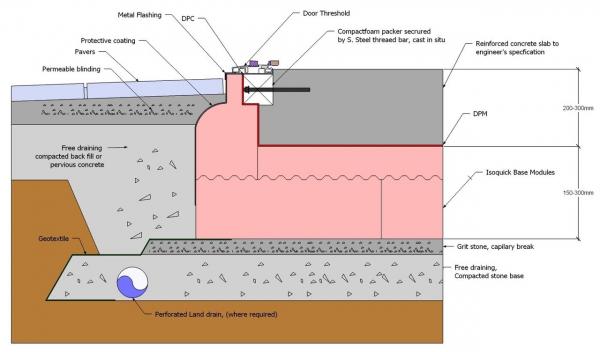

Posted By: Doubting_ThomasWith all credit to Internorm and Isoquick respectively, I've attached a side by side of their details. From what I can make out (there's no direct label) the striped blocks below the extrusion profile on the B&W detail are purenit.

Posted By: djhI understand why you might want Compacfoam/Purenit underneath a door threshold (what is the threshold itself made from?) but why do you want it underneath the windows? Why not mount the windows directly in the main insulation?Do you mean using brackets, or a plywood box? Using Compacfoam looks easier than the latter. Might also be more secure than the former for larger glazing expanses?

Posted By: djhAnd yes, you need to find out how heavy the doors are and how much of that weight is supported by the threshold (could be any proportion from 0% to 100% depending on the type of door). Then use that weight to work out the stress, check that it is within the working limit, and calculate the resulting strain and use that to adjust levels if necessary. Hopefully the strain is near enough zero to ignore.

Posted By: Doubting_ThomasWhilst the entrance and window are both on hinges (i.e. distributed load)

Stress = applied force / cross sectional area

348kg = 3413 N and the cross section is 0.15d x 0.2w = 0.03m²