| Home |

| Green Building Bible, Fourth Edition |

|

These two books are the perfect starting place to help you get to grips with one of the most vitally important aspects of our society - our homes and living environment. PLEASE NOTE: A download link for Volume 1 will be sent to you by email and Volume 2 will be sent to you by post as a book. |

Vanilla 1.0.3 is a product of Lussumo. More Information: Documentation, Community Support.

Posted By: bhommelsI used twistfix

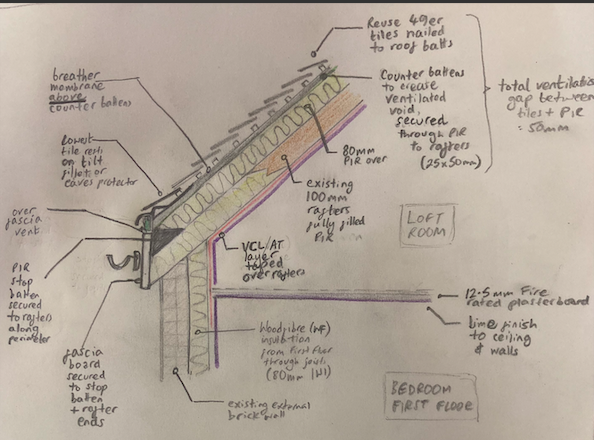

Posted By: Peter_in_HungaryYou have put the breather membrane above the counter battens. Breather membranes usually go below the counter battens The idea of the counter battens is to provide a space between the membrane and the tile battens. Without this space any debris or water running down the membrane will collect at the tile battens and cause premature rot.

Posted By: bhommelsI can only really comment on fixings: I used twistfix to secure the counterbattens to the rafters underneath the PIR....

The detail at the fascia vent/tray is a bit unclear to me. The breather membrane goes over the tray (presumably), how is it held and where does it stop? There seems to be a horizontal bit there which I would avoid.

And what the inside is going to be like, presumably you want some kind of finish over the VCL/AL to keep it in place and to avoid damage?

Posted By: Peter_in_HungaryHi No 33

The squirty foam to which you refer is the ubiquitous Polyurethane foam widely used in the building industry as a quick fix and for sealing around window frames etc. (IMO often used to fill in for poor workmanship).

U value about 0.03.

For insulating between rafters I usually use glass or rock wool as I find it quicker and cheaper especially when the rafters don't match the sheet insulation size.

You have put the breather membrane above the counter battens. Breather membranes usually go below the counter battens The idea of the counter battens is to provide a space between the membrane and the tile battens. Without this space any debris or water running down the membrane will collect at the tile battens and cause premature rot.

Posted By: Dominic Cooney

Your PIR stop-batten should probably be at 90 degrees to the PIR (which is very easy to do), it's to help stop the PIR sliding off the rafters after all.

I think you are supposed to have a greater or equal thickness of PIR over the rafters as there is in between.

Have you checked that the existing rafters are actually 100mm deep? sometimes they are a bit less if they are planed-all-round timber and your 100mm PIR can end up sticking up out of the top or sticking out underneath (just something to be aware of. So you may want 90mm PIR between and 100mm PIR over to solve this.

i don't think you need over-fascia vents with a warm roof, but others may know better.

Posted By: number_thirty_threea Soudal one from Screwfix, but they give a u value of 35I couldn't find any value on the Screwfix site (my problem, I'm sure) but are you sure the 35 value was a U value? It sounds more like a conductivity value in mW/m.K. (i.e. Watts per metre x Kelvin) Divide by 1000 to get a value in W/m.K Still conductivity rather than U value but I wouldn't expect a U-value for foam. (what's the thickness of foam?) I found a data sheet that gives 37.0 W/m.K at https://www.soudal.co.uk/sites/default/files/soudal_api/document/F0031622_0001.pdf

Posted By: number_thirty_threePosted By: Peter_in_HungaryHi No 33

The squirty foam to which you refer is the ubiquitous Polyurethane foam widely used in the building industry as a quick fix and for sealing around window frames etc. (IMO often used to fill in for poor workmanship).

U value about 0.03.

Ok, so it is the same stuff - I've used it in a few places before. Peter, do you have a source for the 0.03 value of this stuff?

Posted By: bhommelsIn the end I went for the Siga recommendation and taped it with their thin foam tape to the top side of the counterbattens. You can let it sag in between but then you might get a fold where it goes over the tray where standing water could form, just where you do not want it!I'm confused by this. If the membrane is over the top of the counterbattens and does not sag, then the membrane touches the bottom of the tile battens and you may get standing water as a result. The reason for the sag is precisely to avoid that possibility of standing water.

Posted By: djhI'm confused by this. If the membrane is over the top of the counterbattens and does not sag, then the membrane touches the bottom of the tile battens and you may get standing water as a result. The reason for the sag is precisely to avoid that possibility of standing water.

Posted By: borpinI'd recommend Lindab steel guttering.

1 to 27 of 27